News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

Ton bag lining bag: A smart choice to ensure material safety

In the modern logistics and packaging industry, Ton bag lining bag, as an efficient and environmentally friendly packaging solution, is playing an increasingly important role. With its unique advantages, it is widely used in agriculture, chemicals, building materials, minerals and other fields, becoming a key link in ensuring material quality and transportation safety.

Ton bag lining bag is generally made of synthetic resins such as polyethylene (PE) or polypropylene (PP) as raw materials. These materials not only have excellent tensile and impact resistance, but also have excellent corrosion resistance and barrier properties, which can effectively resist the erosion of the external environment. The structural design of the lining bag is also ingenious, usually including a main bag body and a top opening, which is sealed by heat sealing, sewing and other sealing forms to adapt to different loading methods and material properties. Some lining bags are also equipped with loading and unloading ports (sleeves), zipper ports and other designs, which further improve the loading and unloading efficiency.

Advantages: Multiple guarantees, efficient and convenient

Protecting material quality: The primary function of the Ton bag lining bag is to protect materials from contamination and damage. During transportation, the liner bag can effectively block external air, moisture, dust and other impurities, and prevent the material from being damaged by chemical reactions, volatilization, moisture, insect infestation and other reasons. This function is particularly important in the chemical industry, as it can ensure the safety and stability of chemical raw materials during transportation.

Convenient loading and unloading and storage: The top opening design of the liner bag makes the loading and unloading process more convenient. By tying or other sealing methods, the liner bag can reduce the scattering of materials during loading and unloading, and is convenient for storage and stacking, saving storage space. In addition, some liner bags are also equipped with a feed port design, making the unloading process more efficient.

Improve work efficiency: The use of Ton bag lining bag can significantly simplify the loading and unloading process, saving manpower and time costs. Liner bags are generally light and easy to carry, and can also reduce the shaking and vibration of materials during transportation, reduce labor intensity, and improve work efficiency.

Excellent environmental performance: The materials of the liner bag can generally be recycled or incinerated, which meets environmental protection requirements. Through cleaning and disinfection, the liner bag can be used multiple times, reducing the generation of waste and reducing the impact on the environment.

Ton bag lining bag is widely used in many industries due to its unique advantages. In the agricultural field, it is mainly used to store and transport bulk materials such as grain and feed, effectively preventing moisture, pests and other factors from affecting the materials. In the chemical field, lining bags are widely used to package and transport chemical raw materials such as fertilizers and plastic particles to ensure the safety and stability of materials. In the building materials, mining and other industries, ton bag lining bags also play an important role, providing strong guarantees for the transportation of various bulk materials.

RELATED PRODUCTS

-

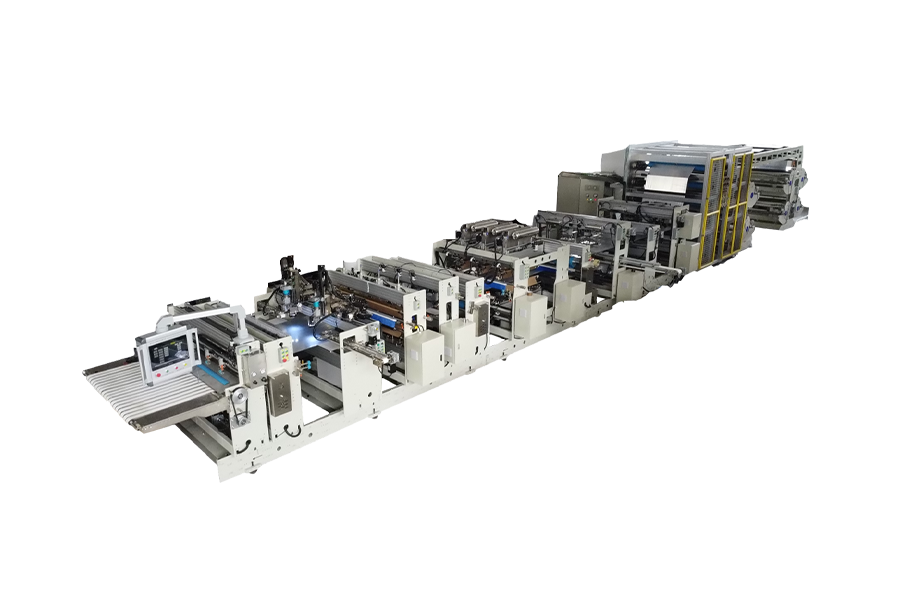

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

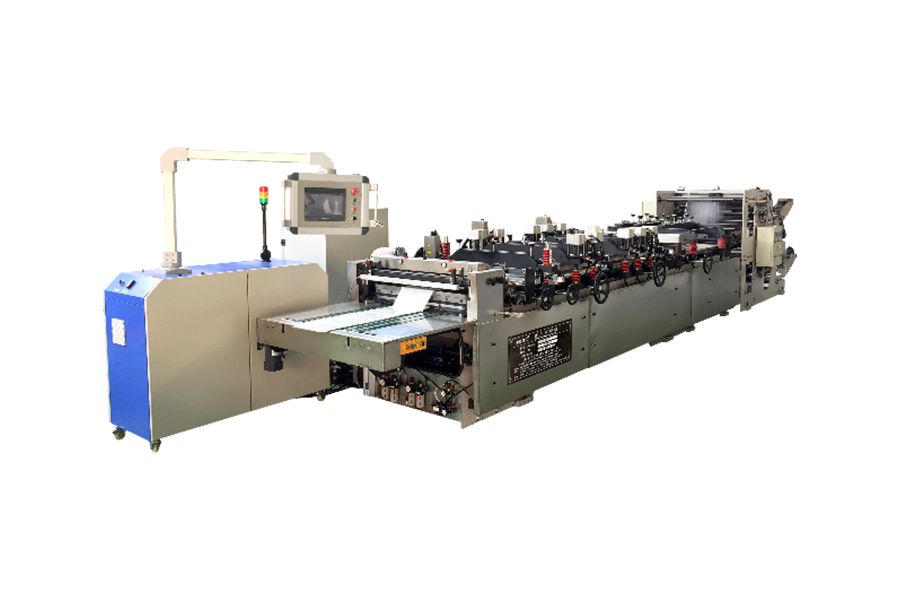

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

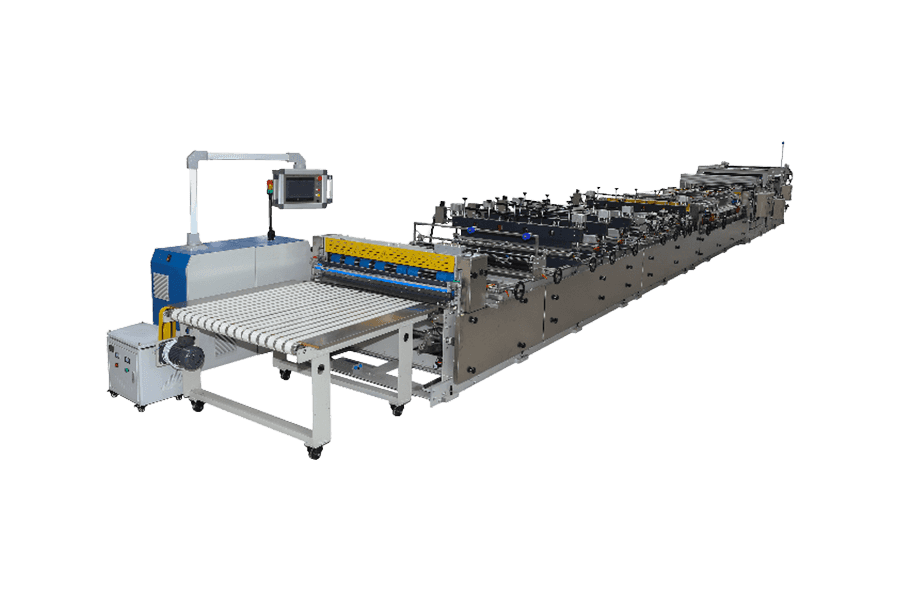

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

amin@delipumachine.com

421948631@qq.com

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

- Panasonic https://panasonic.cn/

- Hansin https://www.asepticbag.com/

- TAILI https://www.zs-taili.com/

- 星辰集团 https://www.www.xcgs.com/

English

English 中文简体

中文简体 русский

русский Español

Español