News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

Valved juice bag: The future of beverage packaging has arrived. Are you still using traditional packaging?

In the ever-changing technological wave, the beverage industry is also constantly exploring and innovating to meet the growing and diversified needs of consumers. Among them, the valved juice bag, as a major innovation in the field of beverage packaging, is reshaping the new form of beverage packaging with its unique design concept and performance, leading the future development of the industry.

For a long time, traditional beverage packaging forms such as glass bottles, plastic bottles and aluminum cans have dominated the market. However, with the development of the times, these packaging forms have gradually exposed some inherent limitations and challenges. Although glass bottles are beautiful and environmentally friendly, they are heavy, fragile, and inconvenient to carry; although plastic bottles are light, they are complicated to recycle and easily pollute the environment; aluminum cans are expensive and difficult to seal and store after opening. These problems have prompted the beverage industry to find a more ideal packaging solution.

It is in this context that the valved juice bag came into being. It cleverly combines valve technology with flexible packaging materials to create a new form of beverage packaging. This packaging not only retains the advantages of lightness, foldability and low cost of flexible packaging materials, but also realizes convenient opening and closing functions through the built-in valve. Consumers can easily enjoy delicious juice with just a light press of the valve button without worrying about spillage or waste. At the same time, the valve also has good sealing performance, which can effectively prevent oxidation and bacterial contamination of juice during transportation and storage, and maintain the freshness and taste of the juice.

The successful launch of valved juice bags is inseparable from the support and promotion of scientific and technological innovation. In terms of material selection, manufacturers use high-performance food-grade soft packaging materials such as PE and PET, which not only have good drop resistance, puncture resistance and barrier properties, but also can withstand certain pressure changes without breaking. In terms of valve design, precision injection molding technology and silicone sealing materials are used to ensure the sealing and durability of the valve.

Today, with the increasing awareness of environmental protection, valved juice bags are also actively practicing environmental protection concepts and promoting the green transformation of the beverage industry. Compared with traditional rigid packaging materials, flexible packaging materials have lower energy consumption and carbon emissions during production and recycling. At the same time, due to the lightweight and foldable characteristics of valved juice bags, space occupation and energy consumption during transportation and storage are also reduced. Manufacturers are also actively exploring recyclable or biodegradable packaging material alternatives to reduce the long-term burden on the environment. These efforts not only meet the trend and requirements of global sustainable development, but also set an example for environmental protection practices in the beverage industry.

With the growing demand of consumers for health, convenience and environmental protection, the market prospects of juice bags with valves are very broad. It can not only be applied to the field of juice drinks, but also can be expanded to other liquid foods, beverages and health products. At the same time, with the continuous advancement of technology and the gradual reduction of costs, the popularity of juice bags with valves will continue to increase.

RELATED PRODUCTS

-

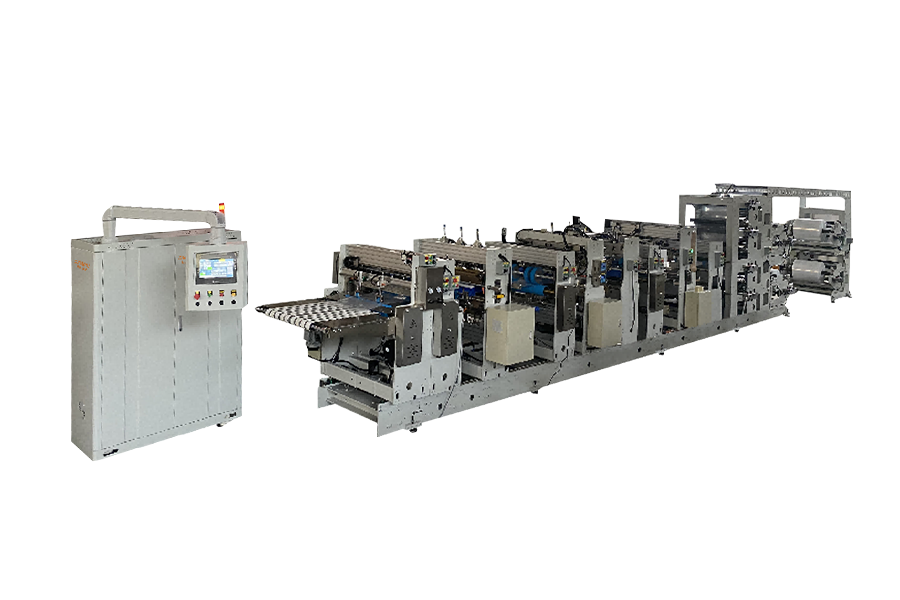

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

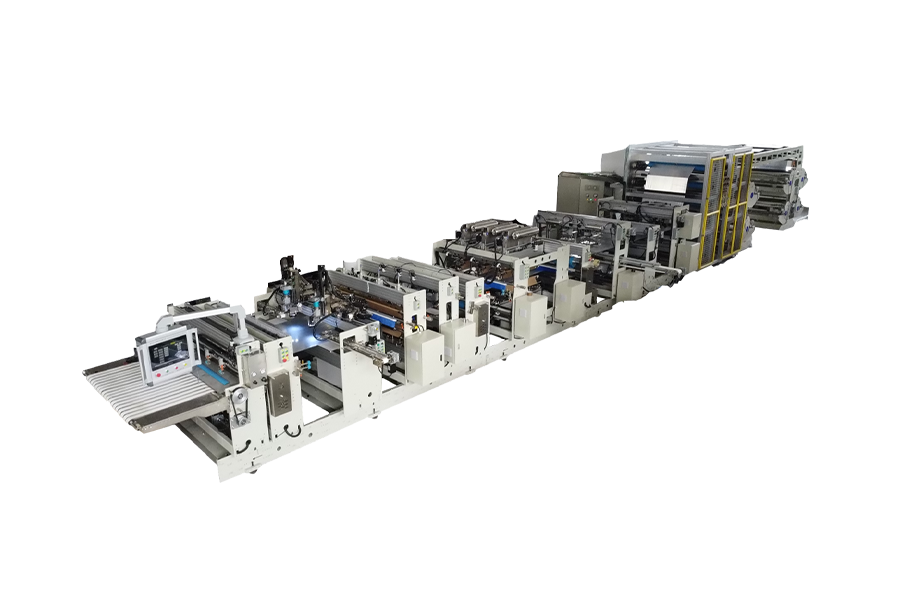

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

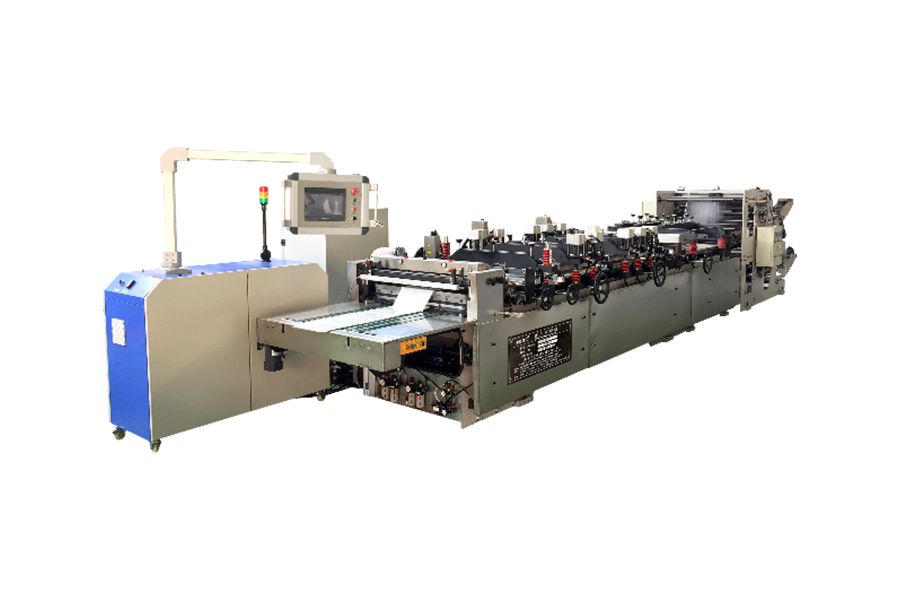

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

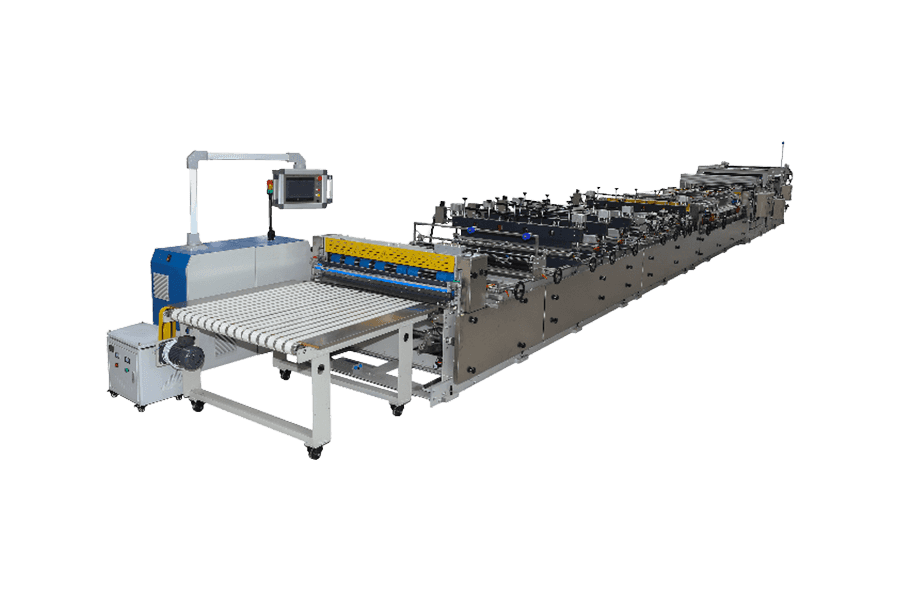

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

- Panasonic https://panasonic.cn/

- Hansin https://www.asepticbag.com/

- TAILI https://www.zs-taili.com/

- 星辰集团 https://www.www.xcgs.com/

English

English 中文简体

中文简体 русский

русский Español

Español