Is the automatic positioning function of Intelligent food bag making machine the key to improving production efficiency and quality?

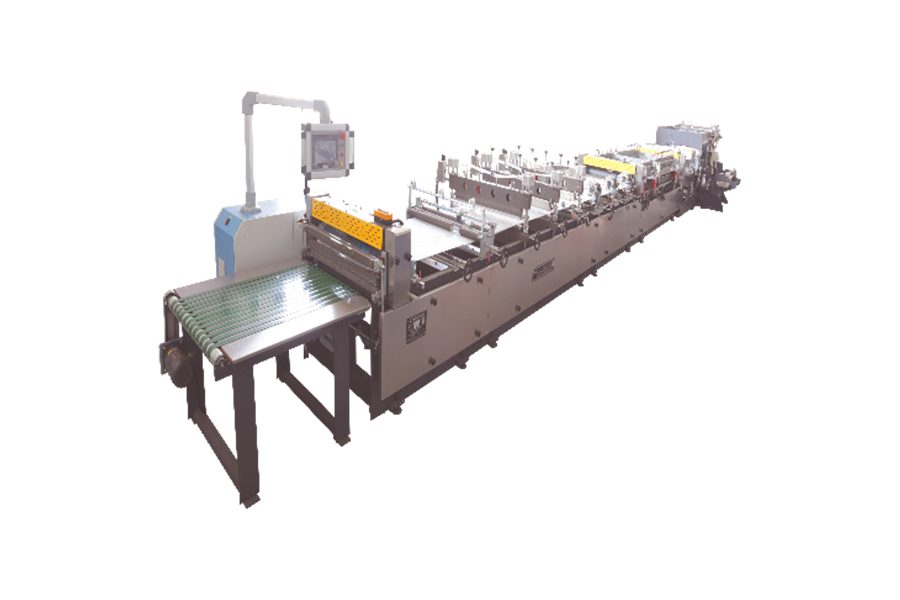

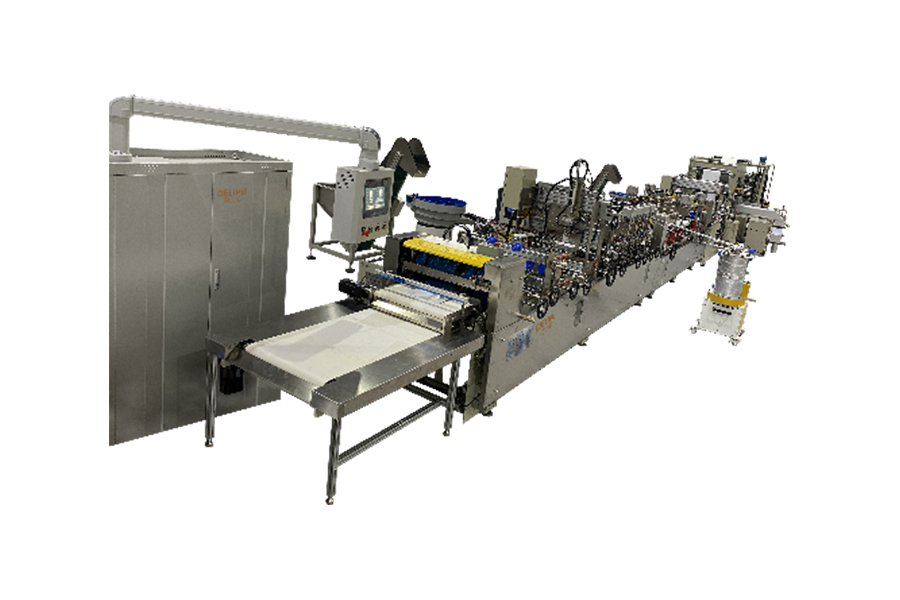

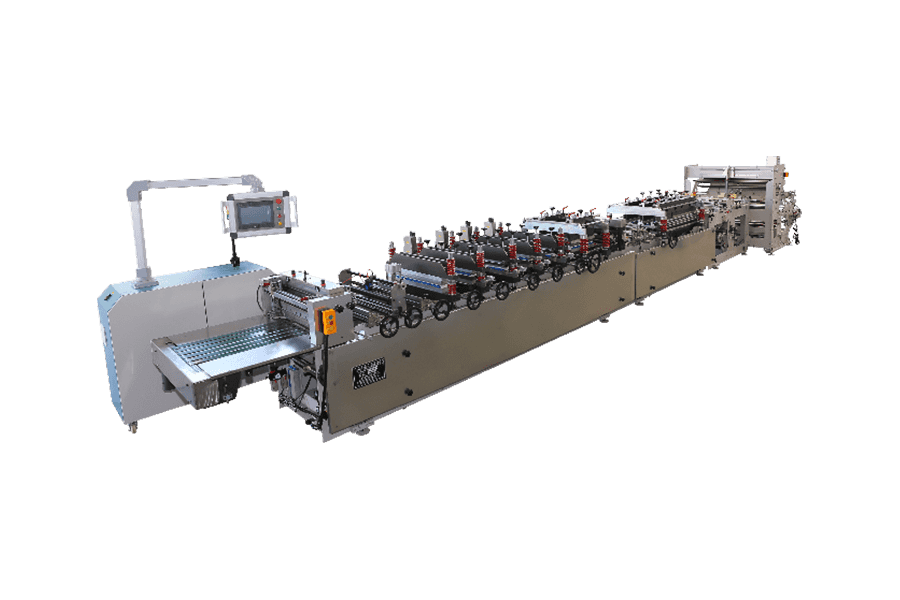

The automatic positioning function of the Intelligent food bag making machine is undoubtedly the key to improving production efficiency and quality. In the production process of food bags, the accuracy of positioning is directly related to the dimensional accuracy, sealing quality and overall appearance of the bag. Therefore, it is particularly important for manufacturers of Intelligent food bag making machines to be equipped with automatic positioning functions.This function is achieved through high-precision sensors and advanced control systems. Sensors can detect the location and size of raw materials in real time, while the control system accurately controls the machine according to preset parameters to ensure that each bag can be accurately positioned. During this process, the machine can not only quickly identify the position of the bag, but also automatically adjust the cutting and sealing positions according to the size of the bag, so that each bag can be processed according to predetermined requirements.

The realization of automatic positioning function greatly improves production accuracy. In the past, inaccurate positioning often led to problems such as bags with different sizes and loose sealing, which not only affected the appearance quality of the product, but also may lead to food leakage during transportation and storage. With the automatic positioning function, these problems have been effectively solved. The dimensions of the bags are more precise and the seals are tighter, greatly improving the overall quality of the product.

The automatic positioning function also reduces scrap rates. Due to accurate positioning, the machine can reduce the generation of scraps caused by inaccurate positioning during the production process. This not only saves production costs, but also improves production efficiency. For enterprises, this is undoubtedly a considerable economic benefit.

Intelligent food bag making machine manufacturers equipped with automatic positioning function play an important role in improving production accuracy and reducing scrap rates. With the continuous advancement of technology and the continuous expansion of application fields, this function will be more perfected and optimized, providing strong support for the development of the food packaging industry.

Will the use of PLC control system in intelligent food bag making machines help improve production efficiency?

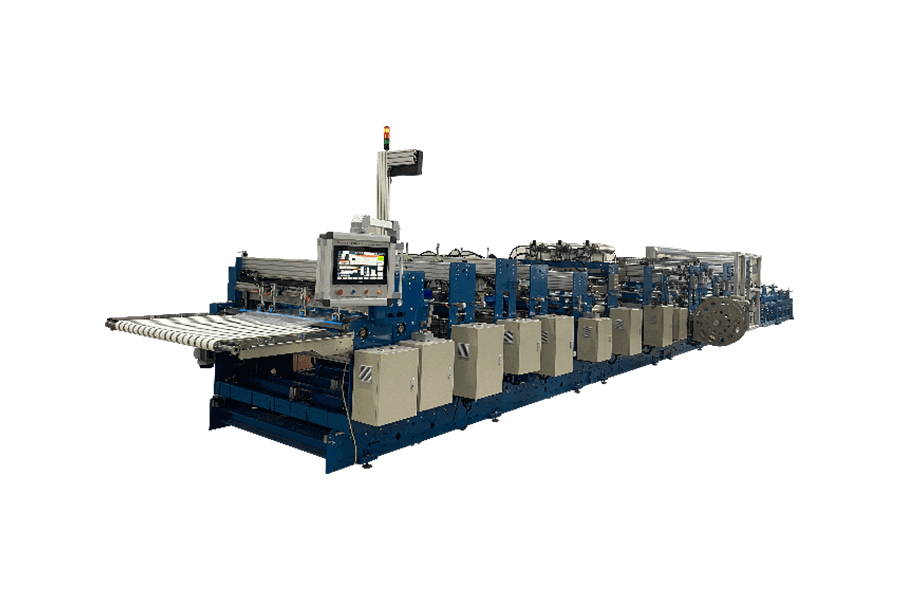

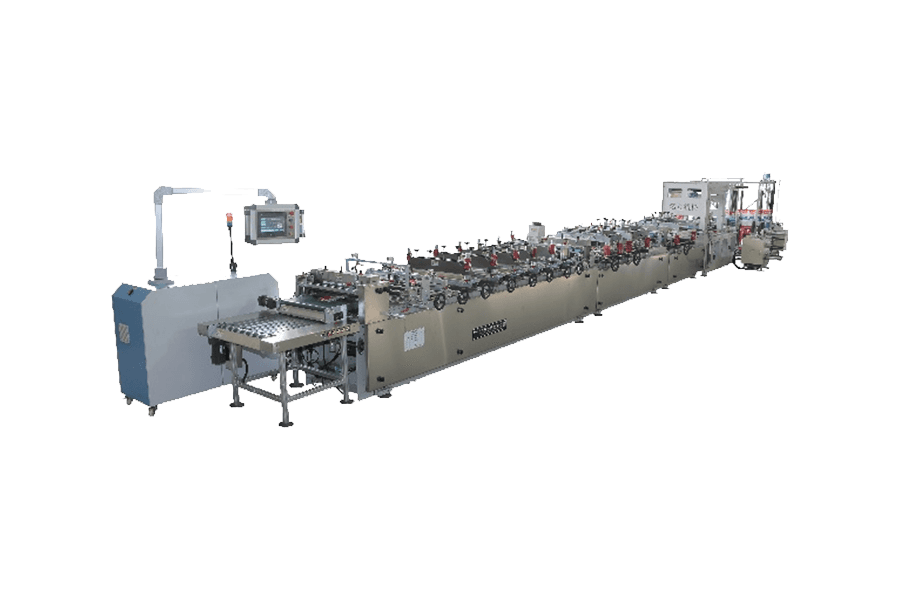

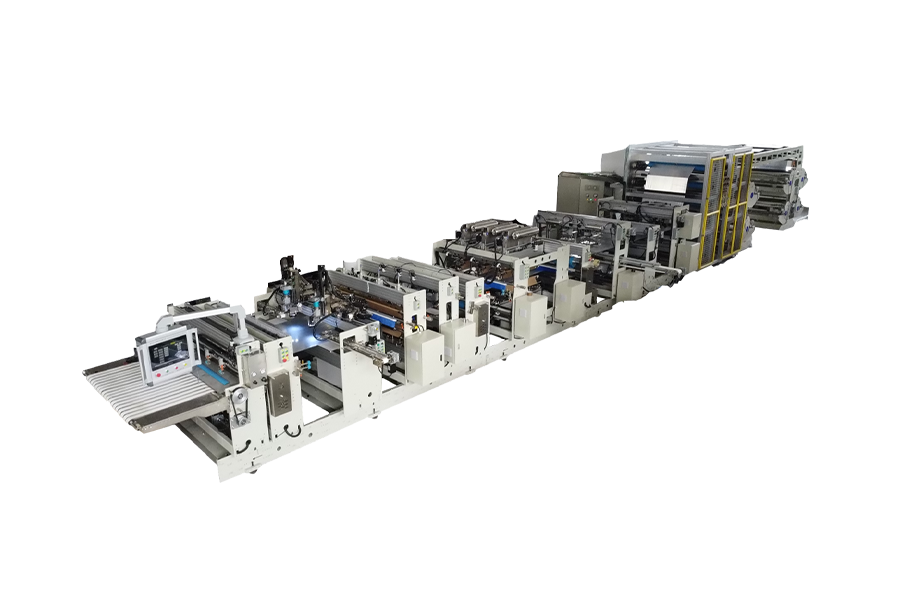

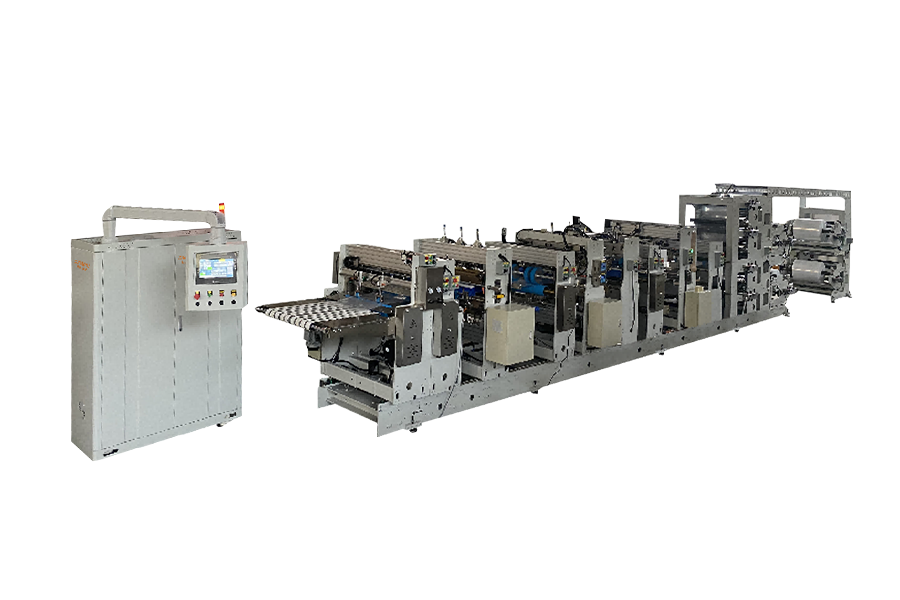

Intelligent food bag making machine, as an important equipment in the modern food packaging industry, its technological advancement and ease of operation play an important role in improving production efficiency and ensuring product quality. What is particularly eye-catching about this PLC control food bag making machine is that it uses an advanced PLC control system and a touch-screen operating interface. This combination greatly optimizes the operating process and improves production efficiency.PLC control system, a programmable logic controller, has powerful logic operations and data processing capabilities and can accurately control various functions of the bag making machine. Whether it is the length and width of the bag, or parameters such as sealing temperature and speed, all can be accurately set and adjusted through the PLC control system. This not only ensures the precise forming of food bags, but also greatly reduces errors caused by human operation.

The touch screen operation interface provides operators with an intuitive and easy-to-use operating experience. Through this interface, operators can easily view the current production status, including real-time data such as production speed and output. At the same time, if there is a fault or abnormality in the equipment, the touch screen interface will also display fault information in time to help operators quickly locate the problem and handle it.

This intelligent operation method not only simplifies the operation process and reduces the difficulty of operation, but also makes the monitoring and management of the production process more efficient. Operators can flexibly adjust parameters according to actual conditions to ensure that the equipment is always running at its best. At the same time, the intelligent fault prompt function also greatly shortens the troubleshooting time and improves the operational stability of the equipment.

The PLC control system and touch screen operation interface adopted by PLC Control food bag making machine manufacturers not only improve the intelligence level of the equipment, but also bring great convenience to the operators. The application of this advanced technology will undoubtedly promote the further development of the food packaging industry.

English

English 中文简体

中文简体 русский

русский Español

Español