News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

Automation and intelligence go hand in hand. How can intelligent bag making (unmanned factory) not lead the innovation of the packaging industry?

With the rapid development of science and technology, the manufacturing industry is undergoing unprecedented changes. As a shining pearl in this change, intelligent bag making (unmanned factory) is leading the future of the packaging industry with its unique charm and huge potential. This innovative production model not only greatly improves production efficiency, but also realizes the automation and intelligence of the production process, opening up a new path for environmental protection and sustainable development.

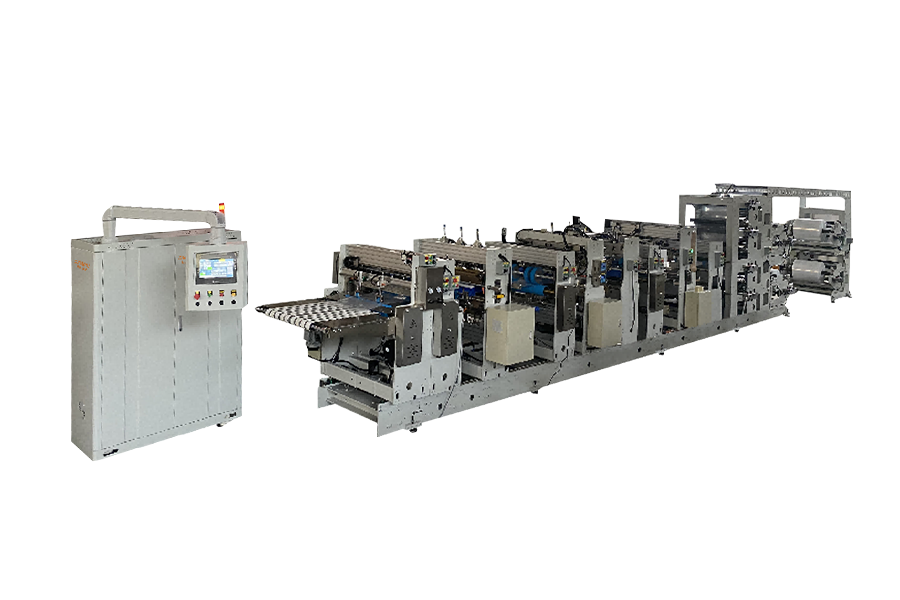

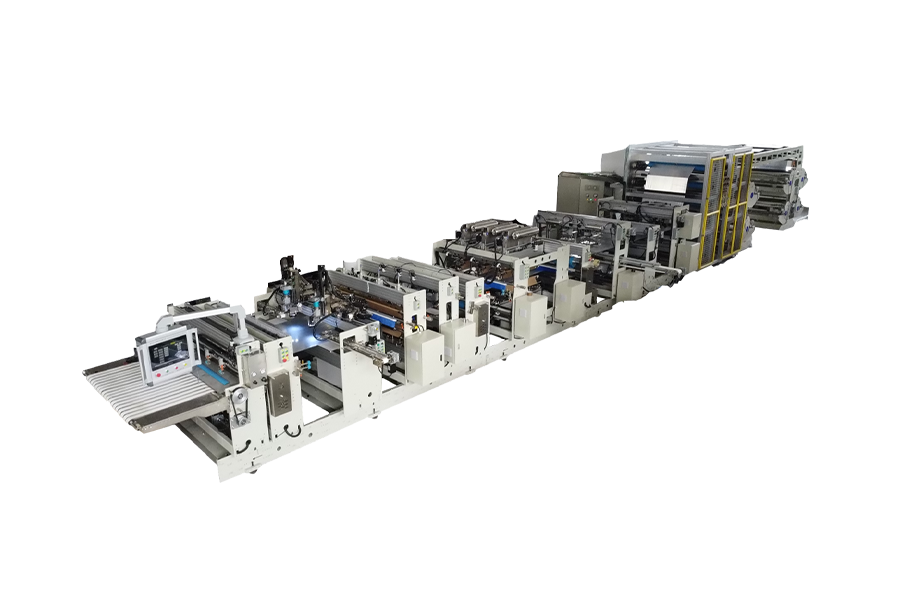

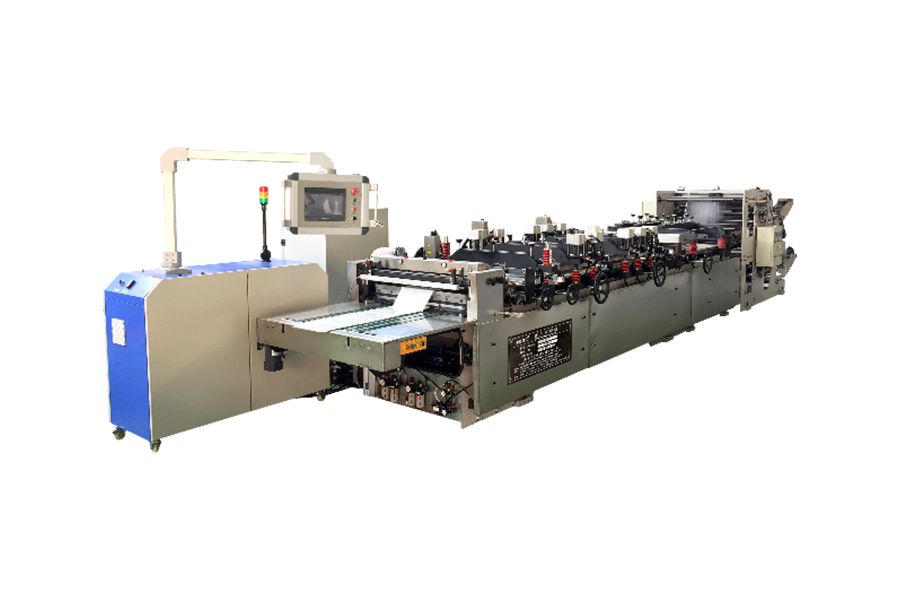

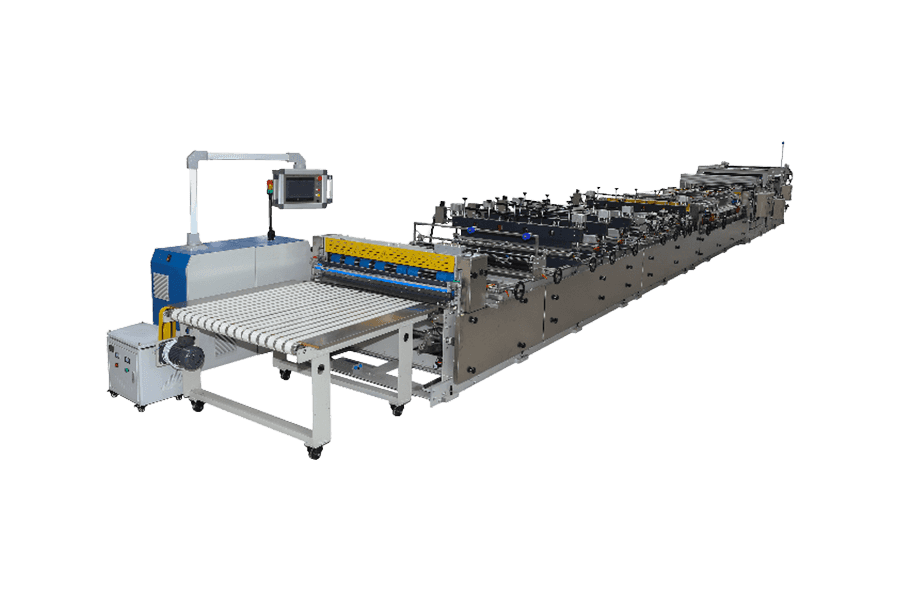

Intelligent bag making (unmanned factory) has completely changed the production mode of the traditional bag making industry by integrating cutting-edge technologies such as advanced automation technology, Internet of Things (IoT), big data analysis and artificial intelligence (AI). From the feeding, folding, ultrasonic bonding, cutting, bag making of raw materials to waste recycling, counting and stacking, the entire process has achieved a high degree of automation and intelligence. This unmanned factory production mode not only reduces the dependence on human resources, but also significantly improves production efficiency and product quality stability.

The intelligent bag making machine adopts advanced technologies such as step-by-step fixed length and photoelectric tracking to ensure accurate and stable production operation. Through the touch screen operation interface, operators can easily set production parameters to achieve flexible adjustment of production speed and diversified customization of product size. Functions such as automatic counting and punching further enhance the intelligence level of the production process and reduce errors and safety hazards caused by human factors. At the same time, the intelligent detection system conducts strict quality inspections on each processed bag to ensure that each product meets high quality standards.

In the context of environmental protection and sustainable development, intelligent bag making (unmanned factory) also shows its unique advantages. Through the residual material recovery system, the waste generated in the production process is automatically collected, realizing the reuse of resources and reducing waste and pollution. Some advanced intelligent bag making equipment can also produce bags made of degradable materials, providing an effective solution to alleviate the problem of white pollution.

The wide application of intelligent bag making (unmanned factory) has brought unprecedented market potential and business opportunities to the manufacturing industry. With the growing demand of consumers for environmentally friendly, convenient and efficient products, various packaging bags produced by intelligent bag making machines have been widely used in many industries such as food, medicine, and chemical industry. Entrepreneurs can take advantage of this trend and achieve scale and efficiency of production by introducing intelligent bag making equipment, so as to stand out in the fierce market competition. At the same time, intelligent bag making machines can also flexibly adjust production strategies according to market demand, develop customized products that meet the characteristics of the industry, and further expand market share.

As a vivid epitome of the intelligent trend of manufacturing industry, intelligent bag making (unmanned factory) is leading the future development of the packaging industry with its unique advantages and huge potential. In the near future, intelligent bag making technology will be widely used and promoted in more fields, bringing more convenience and surprises to human production and life.

RELATED PRODUCTS

-

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

- Panasonic https://panasonic.cn/

- Hansin https://www.asepticbag.com/

- TAILI https://www.zs-taili.com/

- 星辰集团 https://www.www.xcgs.com/

English

English 中文简体

中文简体 русский

русский Español

Español