News

Get A Free Quote !

CALL OUR OFFICE

+86-13606731195 (Mr. Xu)

When food packaging meets intelligent bag making, how can production efficiency and quality stability not be improved?

With consumers' increasing requirements for food safety and quality, the food packaging industry is undergoing unprecedented changes. In this change, intelligent bag making technology, with its high efficiency, precision and hygiene, has gradually emerged in the field of food packaging and has become an important force in promoting the development of the industry.

In the food packaging industry, intelligent bag making technology has achieved full automation from raw materials to finished products. By introducing advanced automation equipment, sensing technology, machine vision and artificial intelligence algorithms, the intelligent bag making system can automatically complete a series of processes such as material delivery, cutting, forming, sealing, and label printing. This not only greatly improves production efficiency, but also ensures the stability and consistency of product quality.

Specifically, intelligent bag making technology can be applied to the production of various food packaging materials, such as plastic bags, paper bags, aluminum foil bags, etc. During the production process, the intelligent bag making system can automatically adjust the process parameters and operation procedures according to different product characteristics and requirements to achieve personalized production. At the same time, by integrating intelligent detection and control systems, intelligent bag making technology can also monitor production data in real time to ensure the stability and reliability of product quality.

In the food packaging industry, intelligent bag making technology has significant advantages. Intelligent bag making technology improves production efficiency and reduces production costs. Automated and intelligent production methods reduce labor costs, shorten production cycles, and enable companies to respond to market demand more quickly. Intelligent bag-making technology ensures the stability and consistency of product quality. Through automatic detection and control systems, the intelligent bag-making system can promptly detect problems in the production process and make adjustments to ensure the stability and consistency of product quality. Intelligent bag-making technology also has the advantages of environmental protection and energy saving. By optimizing the production process and adopting environmentally friendly materials, intelligent bag-making technology can reduce energy consumption and emissions in the production process and achieve green production.

With the continuous advancement of science and technology and the changing needs of consumers, the application prospects of intelligent bag-making technology in the food packaging industry will be broader. In the future, intelligent bag-making technology will pay more attention to the development of personalization, intelligence and environmental protection.

Personalized production will become an important development direction of intelligent bag-making technology. With the increasing demand of consumers for personalized food packaging, intelligent bag-making technology will be able to produce food packaging bags with personalized characteristics according to the different needs of consumers. This can not only meet the personalized needs of consumers, but also improve the market competitiveness of enterprises.

Intelligence will become the core competitiveness of intelligent bag-making technology. In the future, intelligent bag-making technology will continue to introduce new intelligent technologies and algorithms to achieve more accurate, efficient and intelligent production processes. Through intelligent technology, the intelligent bag-making system can automatically learn, self-optimize and adapt to market changes, improve production efficiency and product quality.

Environmental protection will become an important development direction of intelligent bag-making technology. With the continuous improvement of environmental awareness and the continuous tightening of environmental protection policies, intelligent bag-making technology will pay more attention to environmental protection and sustainable development. By adopting environmentally friendly materials and optimizing production processes, intelligent bag-making technology can reduce energy consumption and emissions in the production process and achieve green production.

Intelligent bag-making technology has broad application prospects and huge development potential in the food packaging industry. With the continuous advancement of technology and the continuous changes in the market, intelligent bag-making technology will play a more important role in the future food packaging industry.

RELATED PRODUCTS

-

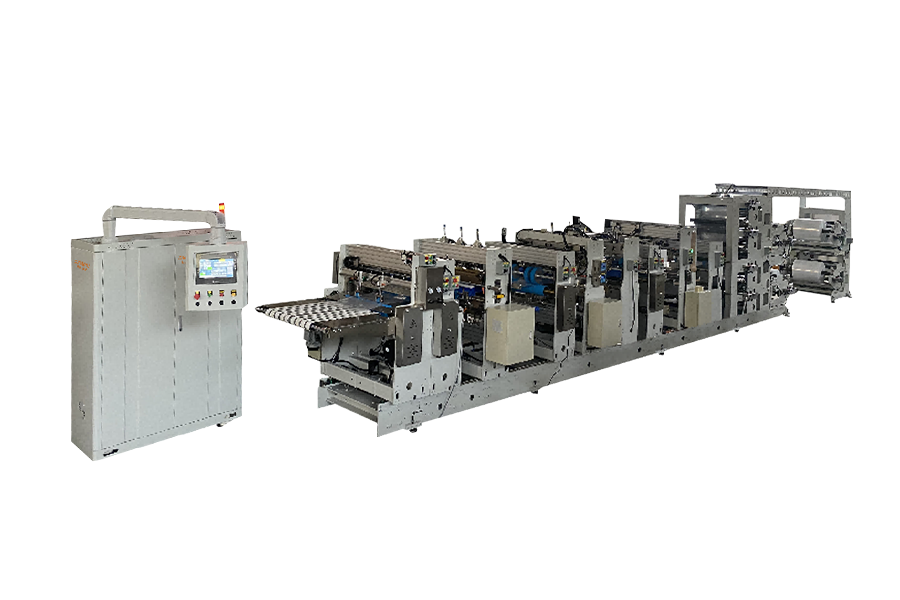

DLP-600 intelligent BIB bag-in-box bag making machine

The DLP-600BIB Box-in-Bag Intelligent Bag-Making Machine is ... View More

-

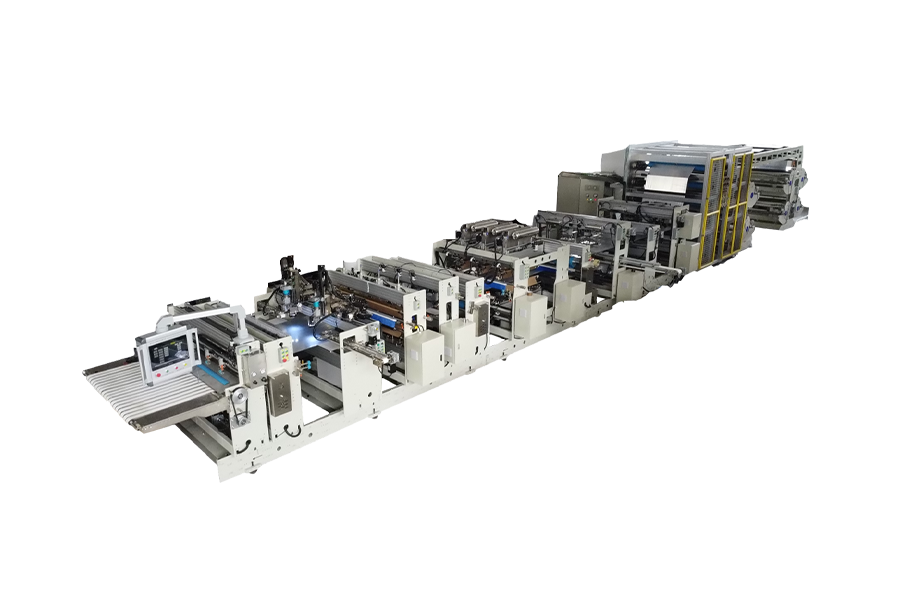

DLP-1600 intelligent BIB bag-in-box bag making machine

The DLP-1600BIB Box-in-Bag Intelligent Bag-Making Machine is... View More

-

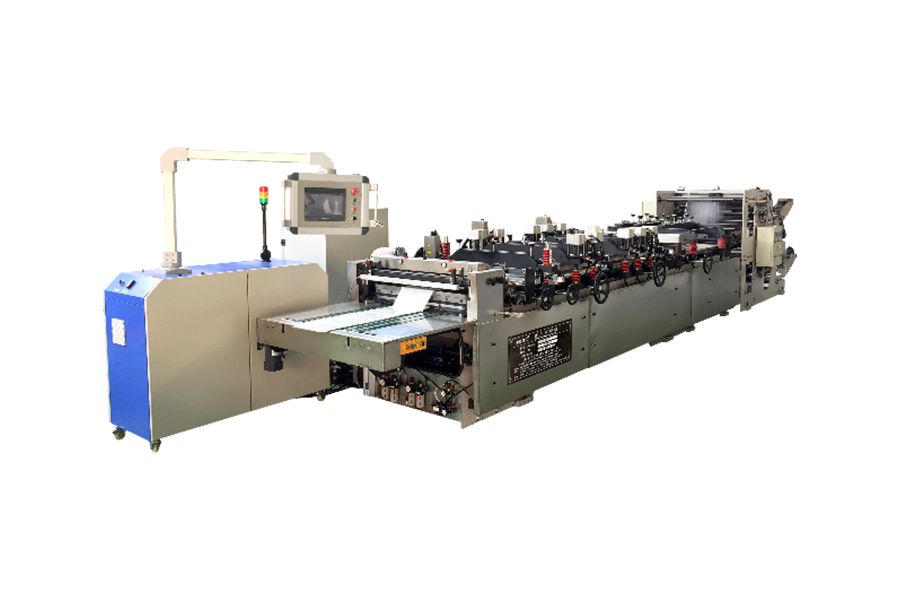

DLP-1300DD medical high temperature sterilization pouch/header bag making machine

DLP-1300 medical high temperature sterilization bag/header b... View More

-

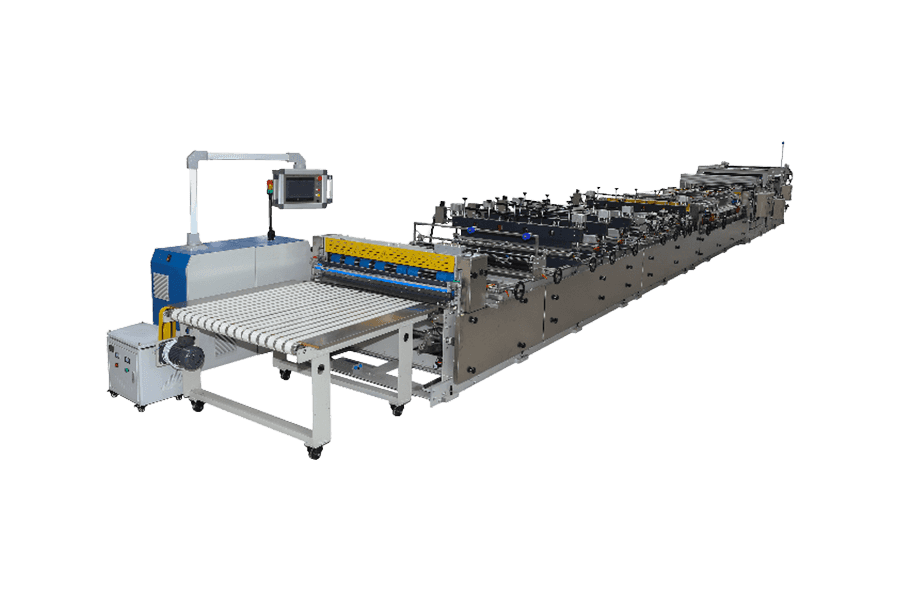

DLP-600 medical paper plastic composite bag making machine

DLP-600 medical paper-plastic bag making machine is suitable... View More

-

DLP-4500 sealing machine

The DLP-4500 sealing machine is in particular designed to se... View More

-

DLP-1300 vacuum storage compression bag making machine

The DLP-1300 vacuum compression bag making machine uses adva... View More

-

PHONE

+86-13606731195 (Mr. Xu)

-

EMAIL

-

ADDRESS

East side of Industry Road and north side of Pandan Road, Tongxiang Economic Development Zone (Gaoqiao Street), Jiaxing City, Zhejiang Province, China

-

FOLLOW US

- Panasonic https://panasonic.cn/

- Hansin https://www.asepticbag.com/

- TAILI https://www.zs-taili.com/

- 星辰集团 https://www.www.xcgs.com/

English

English 中文简体

中文简体 русский

русский Español

Español